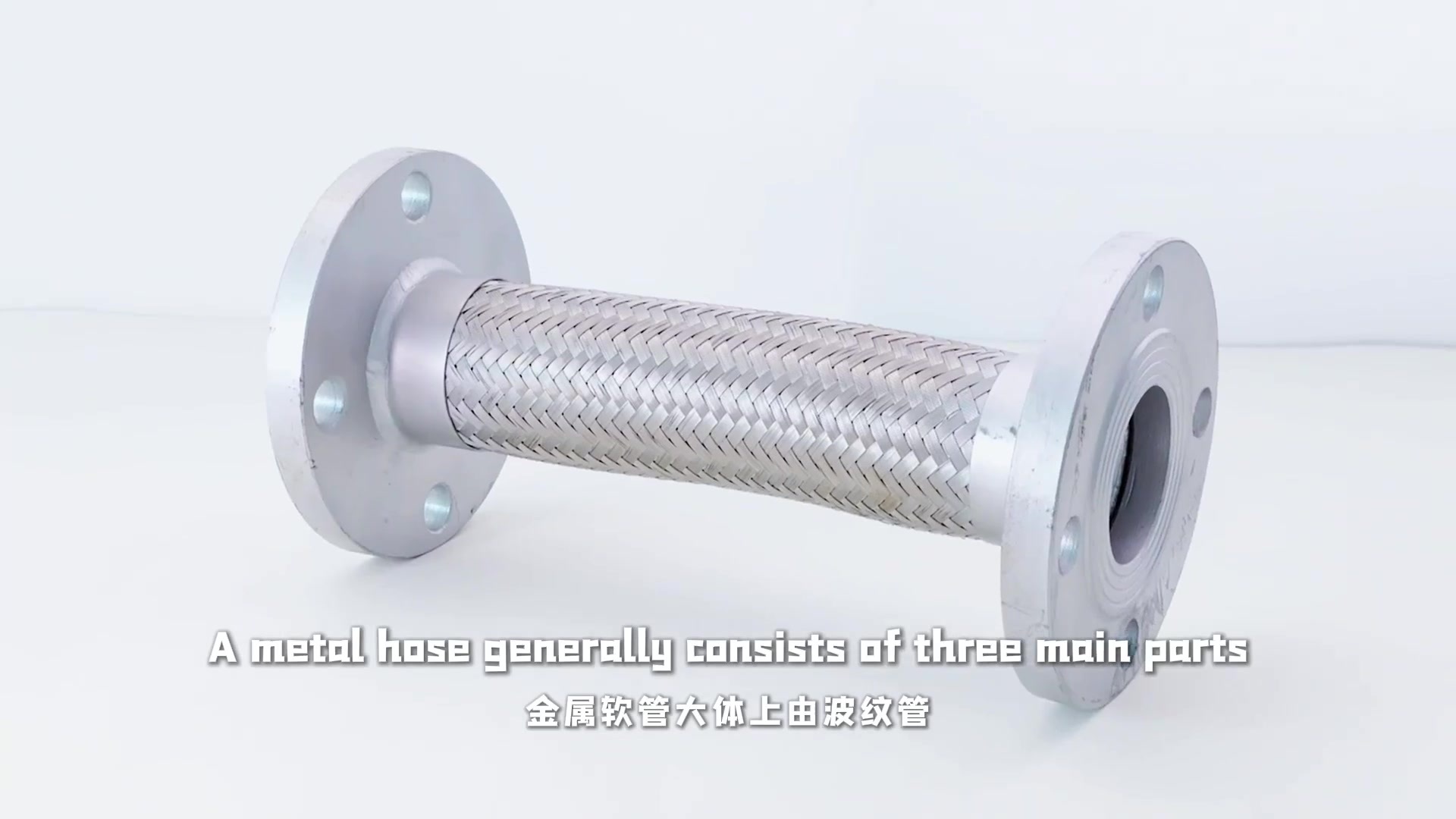

HY-Stainless Steel Flange Metal Hose

The metal hose is generally made up of the three parts: the corrugated pipes,mesh sleeves and joints.

Subsidiary Classification:

Products

Product Characteristics

A metal hose generally consists of three main parts: the corrugated pipe, the braid, and the fittings.The corrugated pipe is the main body of the metal hose and provides flexibility; the braid reinforces and shields the hose; and the fittings are used for connection.Depending on different usage requirements, the connections between these parts can vary.The hose ends can be made with various connection types beyond just threaded or flanged standards, facilitating ease of connection and use.

Areas of application

It is characterized by lightweight installation, good flexibility and bend radius, resistance to corrosion, high temperatures (up to +420°C), and low temperatures (down to -196°C), as well as eliminating expansion and contraction stresses caused by temperature variations.

Product Specification

Note:

1. Due to so many models and limited pages, larger caliber and special caliber or materials are subject to our client's requirements.

2. Please do not hesitate to contact our after-sales persons for installation instructions and the problems with which you got into trouble while being installed or used and we will reply to you in time.

Explanation video

Stainless Steel Flange Metal Hose

FAQ

Are you a factory or a trading company?

How to place an order?

What about sample orders?

What shipping methods are available?

How long is the delivery production and shipping time?

Some products are missing from my package. What should I do?

How to confirm payment?

Certificate

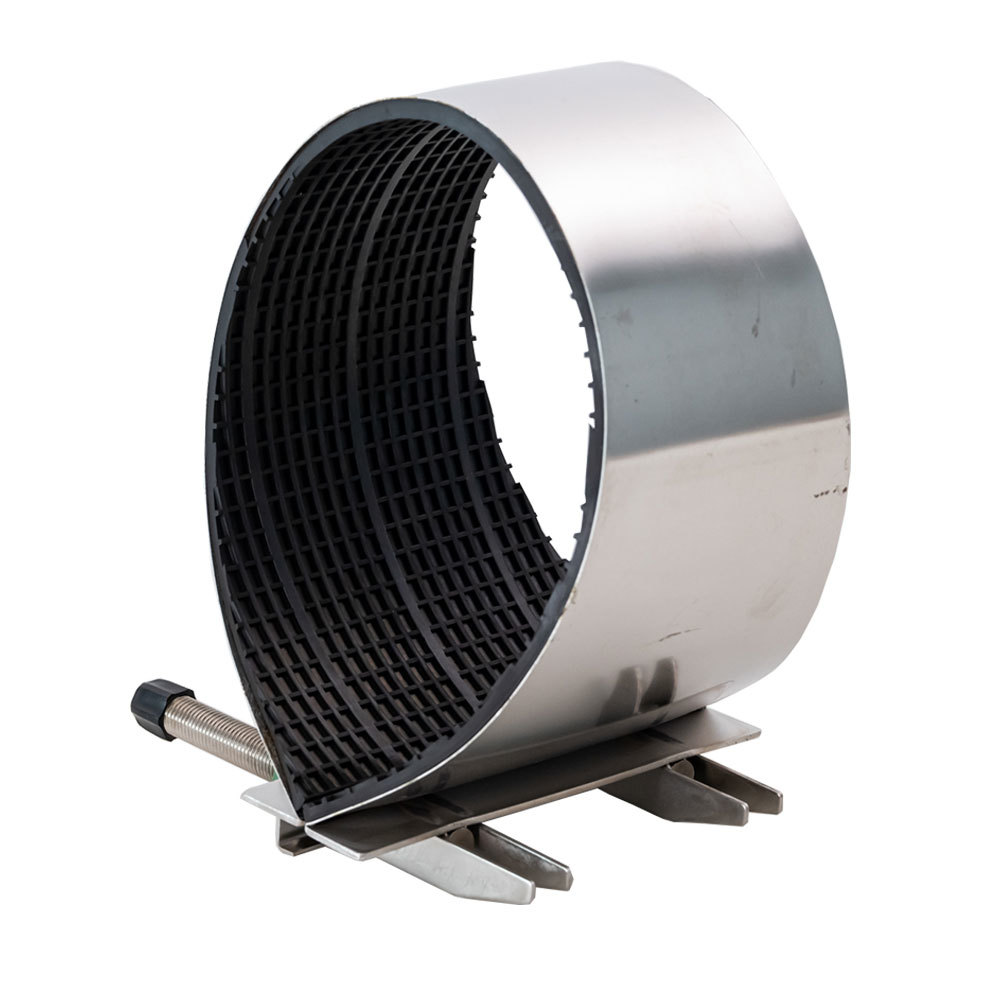

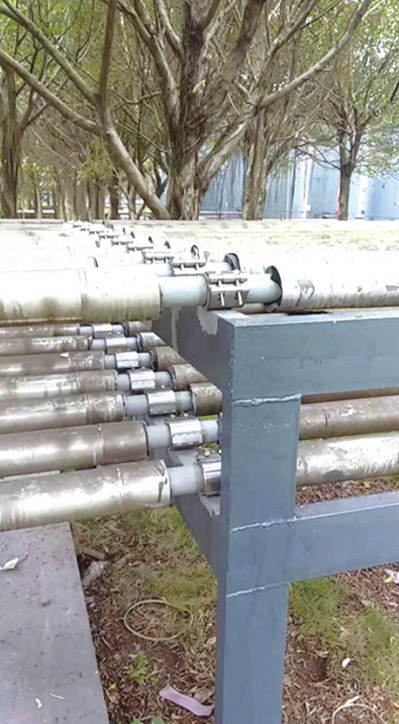

CHARACTERISTICS AND USE

With anti-seismic, anti-impact and noise reduction elements:

The connector and repair device of this type changed the traditional rigid connection to the flexible one favorable to a status in which the pipes are of anti-impact & vibration and denoise.They themselves are resistant to the 350g acceleration impact within 0.02 seconds.By comparison with the flange way, the noise intensity is possible to be lowered by 80%, conducive to the utilization of the entire pipes system in a safe and normal way including the pump, the valve and the instruments, etc. prolonging service life.

Reduction in pipes weights:

The reduction in weight is attainable by about 75% compared to the one by flange way.

Saving in Pipes space:

Assembly and disassembly process do not require a full-phase construction by flange way, but only screwing the bold from one side, causing a saving of up to 50% both in pipes layout and construction space, being of great significance for the ships with space less available in configurating pipes system rationally.Flexible connection permits alternate angle 10 between the axis of two pipes, deviation angle 6 of single pipe,spacing of up to 5-35mm in pipes end.The loose tolerance limits avert the requirements of a high-precisionassembly,conducive to the promotion of advanced process structure measures such as the construction of the general section and the vibration isolation and noise reduction of the "Floating Raft" in the shipbuilding industry. There is no adverse effect on pipe connectors or repair device arising from the deviation in shipbuilding installment or the shifting made by the navigation.

High Cost Performance:

The construction expenses of the connectors and repair device are more economical than that of the flange. The individual cost is slightly higher than that of the general flange, but with long service life and high cost performance. In respect of the copper-nickel and stainless steel pipes, the individual cost is lower than or close to that of the medium diameter copper-nickel and stainless steel flanges.

Easy Maintenance:

When the pipes are under repair, even if there are the oil and water in them, no heating process should be done because of the disconnection of the welding, hence away from the danger of the fire or explosion. The rush repairs are applicable to the dual or open or foldable repair devices from outside all kinds of broken pipes in a bandaged way.

When our products are applied to the newly laid pipes project, the best economic result is achievable in terms of the manpower, material and financial resources.

lt sunnecessary to do plastic and smooth treatment in special on the end face and surface of the pipes at the construction site, only wipe off the soil for the installation provided there is no special deformation at the end of the pipes.

lt usually takes about 5 minutes to install a connector and only 10-20 minute to operate a repair device online.When working in a confined space in particular, it has more obvious advantages. One or two operators are enoughin general.

Our product is not influenced by the varied pipe materials and can be used effectively while the difference of pipes diameter and axis deflection angle are within specified scope.

APPLIANCE

Product Message

Other Products

CONTACT US

Add:No.16 Factory Building, China Energy Conservation Industrial Park, Fenghuangshan Road, Yangting Town, Huanjui District, Weihai, China